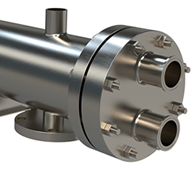

Sanitary Heat Exchangers

Sanitary shell and tube heat exchangers are designed for the efficient transfer of heat between two fluids while maintaining a high standard of hygiene. These heat exchangers consist of a series of tubes, one set carrying the hot fluid and another the cold fluid, enclosed within a larger shell. The design ensures that the fluids do not mix, allowing for effective temperature regulation. Widely used in industries where cleanliness is paramount, such as food and beverage processing, pharmaceuticals, and biotechnology, these heat exchangers are constructed with materials that meet strict sanitary standards, including stainless steel and other corrosion-resistant alloys. Their surface finishes are polished to minimize contamination risks, and they often include features like easy disassembly and cleaning to maintain optimal hygiene.

- Applications: Used in food and beverage processing, pharmaceuticals, and biotechnology.

- Sterilization and Pasteurization: Critical for processes like pasteurizing beverages and sterilizing pharmaceutical compounds.

- Heat Transfer: Capable of handling large temperature differences, making them suitable for demanding applications.

- Corrosion Protection: Features enhanced corrosion protection for longevity, even in aggressive processing environments.

- Enhanced Product Quality: Maintains consistent temperatures, which is crucial for preserving the quality of temperature-sensitive products.

- Automated Control Systems: Can be integrated with automated systems for precise control and monitoring of temperature and flow rates.

Sanitary 3A:

Dairy and Pharmaceutical

- 3A Certified

- USDA & FDA Approved

- 304L or 316L SSP

Sanitary:

Dairy, Food & Beverage

- Clean & Drainable

- Meets Sanitary Standards

- 304L or 316L SSP

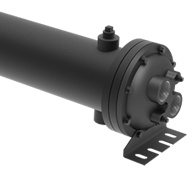

Industrial:

High Temperature Applications

- Steam to Water

- Carbon Steel or Stainless

Sanitary Applications

Sanitary shell and tube heat exchangers are versatile and essential in various industries where maintaining cleanliness and preventing cross-contamination are critical. In the food and beverage industry, they are used to pasteurize dairy products, beverages, and other consumables, ensuring they are safe for consumption. In the pharmaceutical sector, these heat exchangers are integral in processes like sterilization and temperature control of sensitive compounds. Additionally, the biotechnology industry relies on these devices to maintain the integrity of biological materials during fermentation and other processes that require precise thermal management.